Running a ‘green’ or environmentally friendly fleet is no longer just a trend, it’s a financial necessity. With the cost of fuel averaging nearly 45% of fleet running costs, the need to optimise has become a financial as well as an environmental concern.

At the beginning of 2016, the South African government officially put in place comprehensive policies to lower local CO2 emissions, and many local businesses have been put under immense pressure as a result. In the bigger picture, this legislation is necessary: South Africa is responsible for about 1.6% of global greenhouse gas (GHG) and is the biggest producer of GHG on the African continent – roughly half of Africa’s total CO2 emissions come from South Africa alone. So yes, something needs to be done. (Note: GHG consists of various harmful gases, but the main component is C02).

According to Willie Venter, former Fleet Consulting Manager at EQSTRA Fleet Management, “the new carbon tax acts as an incentive for businesses and individuals to change the way they operate by constantly keeping pollution in mind. The upside to reducing your consumption and emissions is that it will reduce cost, increase profitability and also boost brand reputation.”

With a ‘green fleet’ being the big new thing in sales pitches, Willie cautions fleet managers to do plenty of research before committing to new vehicles or fleet management systems. “Make sure you’re getting the real deal and not just a green sales pitch”, he says. “Fleet managers can’t manage the carbon footprint of their fleet unless they can measure it. Companies need to have measurement tools and methods in place to get an accurate picture of their overall emissions. This will also allow them to plan their fleet strategy to adapt and comply with the increasingly strict CO2 legislation.”

The South African government has committed to reducing local GHG emissions by 34% by 2020 and by 42% by 2025. This is a very ambitious target and in order to achieve it, the government has to be strict with its tax policies to ensure compliance from businesses.

South Africa’s current emissions tax works off a baseline figure of 120g/km – anything above 120g/km starts incurring tax. Most manufacturers list the CO2 tax incurred per vehicle and it’s a once-off fee that’s included in the purchase price.

That said, local CO2 legislation is set to become stringent and companies will be subjected to CO2 audits. It’s therefore crucial that fleet managers know exactly how much CO2 their fleet is producing.

In order to get a clear picture of your fleet’s carbon footprint, fleet managers need to get accurate data on the following:

Driving emissions

Driving emissions is the amount of GHG emitted by a vehicle every kilometre. Unfortunately, contacting the manufacturer or reading the vehicle spec sheet will not give you an accurate figure. Manufacturers tend to test all their vehicles under the same, controlled conditions – this allows for consistency on their part. Manufacturer figures are fine when you need to compare the efficiency of different vehicles, but their emissions figures are not an accurate representation of everyday use.

“This is why data is so important”, says Willie, “companies who can compare their actual year-on-year fuel consumption, can easily work out their actual emissions.”

Fuel consumption

Fuel consumption is calculated in litres per 100 kilometres, which can be used to determine exactly how much each vehicle is using per kilometre. This consumption-per-kilometre figure is then used to determine actual emission-per-kilometre for every vehicle.

How to calculate emissions per kilometre

Don’t worry, this is not as tricky as it sounds (but you may want to print this out for reference).

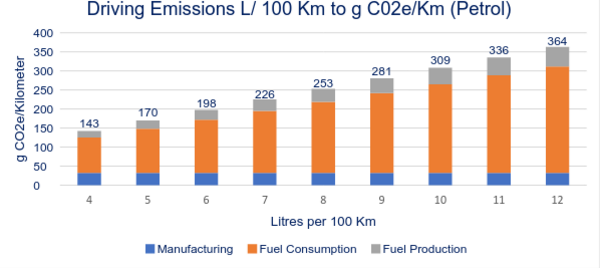

Emissions per kilometre are calculated using driving emissions (mentioned above) as well as the emissions produced during the manufacture of the vehicle and those produced when in the fuel production process. Luckily there’s a universal standard for vehicle and fuel production emissions, so you don’t need to interrogate everyone along the food chain.

These universal standards are:

- Vehicle Manufacturing emissions: 32g CO2e/km (CO2e means Carbon Dioxide Equivalent)

- Fuel Manufacturing emissions: 2.33kg CO2e/litre

Remember the actual fuel consumption mentioned in Point 2? Let’s say it came to 8 litres/100 kilometres. In order to calculate the emissions of that specific vehicle, use the following:

- Calculate fuel production emissions: 8 L/100km x 2.33 -/- 100 = 186 g CO2e/km

- Calculate manufacturing emissions: 8 L/100 km x 0.43 -/- 100 = 34 g CO2e/km

These two calculations, along with your driving emissions, will give you the true emissions figure for each vehicle. That figure will be used to calculate your emissions tax, so it’s crucial for fleet managers to have accurate data. The below graph illustrates the calculations explained above:

Just to add some method to this madness, note that the above graph and calculations are all based on petrol. There are many other types of fuel, such as diesel, LPG, CNG etc. Each of these types of fuel has different properties and their emissions are therefore calculated using different variables.

How fleet managers can reduce emissions

The deciding factor here is fuel consumption: fleet managers who reduce the overall fuel consumption of their fleet will thereby reduce their CO2 emissions and their overall carbon footprint. Below are some top tips to keep consumption and emissions to a minimum:

-

Choose the vehicles Fleet managers need to look for vehicles that offer the perfect balance between power and efficiency that suits their fleet needs. This takes plenty of research and a lot of experience.

- Vehicle maintenance

It is vital to ensure vehicles are well-maintained and running at their best. A vehicle is, essentially, one large organism and if all the parts aren’t functioning properly it will have a knock-on effect that can result in higher fuel consumption.

- Route planning

The shortest route may also be the one with the most inclines or traffic lights which will burn more fuel than a slightly longer route with fewer stops. Always keep road conditions in mind when doing your route planning as this directly affects how much fuel will be used.

- Tyres

Underinflated tyres can result in a huge increase in fuel consumption. By ensuring tyres are in good condition and properly inflated, fleet managers can save a lot of money on fuel and also reduce the overall fleet emissions.

- Driving behaviour

The way you drive a vehicle directly impacts fuel consumption and emissions. Erratic acceleration, speeding, sudden braking, over-revving and long periods of engine idling will all push up fuel consumption and emissions.

- Technology

By investing in good fleet management technology, companies can keep track of all the above factors and make adjustments when necessary.

Over the next few years, fleet managers will feel increasing pressure from both the government as well as company directors to keep fleet consumption and emissions to a minimum. Fleet managers who understand how consumption and emissions work - and how to reduce these – will be way ahead of the game and capable of reducing the overall carbon footprint of their fleet.